On the Way to a Sustainable Future

At KOTI, sustainability is a core value. As a manufacturer, we feel responsible for the impact of our production on people and the environment. That’s why we continuously strive for more efficient processes, more economical use of raw materials, and structural reduction of our ecological footprint.

Sustainable Mobility

✓ Energy-efficient production methods

✓ Fully electric/hybrid vehicles

✓ Transport with trucks running on HVO100 (90% less CO²)

Environmental benefit: Less air pollution, significant CO² reduction

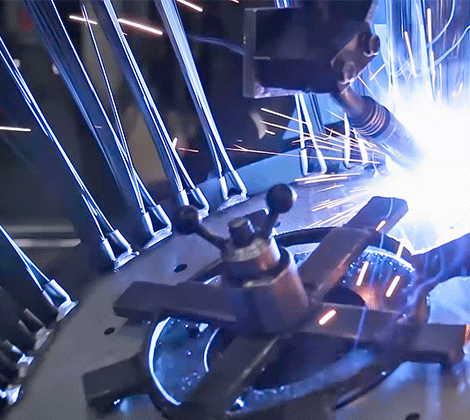

In-house Production

✓ Brushes from our own factories

✓ Control over quality, processes, and sustainability

✓ Local delivery and shorter supply chains

Environmental benefit: Less transport, lower emissions, sustainable control over production

Circular Material Use

✓ Grinding and reusing residual materials

✓ Refurbishing returned brushes from customers

✓ Strict waste separation and recycling

Environmental benefit: Less waste, less raw material extraction, lower environmental impact

Research and development

✓ Development of more sustainable brushes

✓ More efficient material use

✓ Continuous improvement of environmental performance

Environmental benefit: Lower environmental impact per brush

Sustainable Energy via Solar Panels

✓ Own generation of green electricity

✓ Feeding energy back to the grid on weekends

Environmental benefit: Less dependent on fossil fuels

Social Return

✓ Jobs for people with limit access to the labor market

✓ Production support through social workplaces

Environmental benefit: Local production and social impact for sustainable growth

Employee Involvement

✓ Internal campaigns on energy and material consumption

✓ Sustainable initiatives suggested by staff

Environmental benefit: Less waste, sustainable work culture at all levels

ISO Certification

As a quality-conscious producer, we work according to ISO 9001 standards and are actively working towards obtaining ISO 14001, the international standard for environmental management. These certifications confirm our commitment to process control, continuous improvement, and sustainable business practices.

- Consistent product quality

- Transparency towards auditors and procurement

- Collaborating with a party that demonstrably operates sustainably

Production

In-House

We produce all our brushes entirely in-house, from design to assembly and quality control. This ensures short lines, reliable delivery times, and maximum control over quality and sustainability. Thanks to local production, we limit transport, shorten the supply chain, and reduce CO² emissions. Moreover, we can quickly respond to customization and specific customer requirements.

- Short supply chains and fast delivery within the region

- Consistent quality and sustainable production processes

- Transparency about origin, material use, and performance

Toolbox Meetings Sweeping brushes

The right brush choice, adjustment to the surface, rotation speed, and pressure make a big difference in lifespan and performance. In our Toolbox meetings, we share practical tips tailored to your situation. This is how KOTI helps you get the most out of every sweeping or weed brush with less wear, lower costs, and reduced environmental impact.

- Longer brush use = less replacement = cost savings

- Reduced CO² impact through more efficient use

- Better grip on performance in the field

Your success is our success

Brush refurbishment

A core construction can be a costly component of a brush. It’s always wise to check if the core is eligible for reuse. Our technical experts have all the knowledge to assess whether we can provide your KOTI-brush with new filling materials. After all, we develop and produce the initial brushes entirely in-house.

Wear limit

Once the filling material of your KOTI-brush reaches the wear limit, you can send the worn brush back to KOTI.

Quality check

We check the overall core structure for any defects, check tolerances and any bearing, and remove the old fill.

Refurbishing

After the core construction is approved, the brush will be refurbished. We remove the old filling materials and replace the core with new ones. This process is carried out in our specialized factory.

Your brush, as good as new

You will receive the same core with new filling materials. This is how we reduce our ecological footprint together.

Your success is our success

Want to optimize your process?

Ready to take your process to the next level? Our specialized consultants will be happy to help.