Brush belt toothed

The belts of the brush belt toothed are made of polyurethane. These brush belts are driven by toothed belt pulleys. This type of brush belt is mainly used when you want to positioning or transfer products. The major advantage of the toothed belt is timing. The belt runs over toothed pulleys, preventing slippage and ensuring correct timing. As a result, the rotational speed can be precisely set and reach up to 6 m/s. The filling density is limited here, as only a restricted space for brush fibers is available on the top side of the belt. This means that the filling is always relatively open.

Models

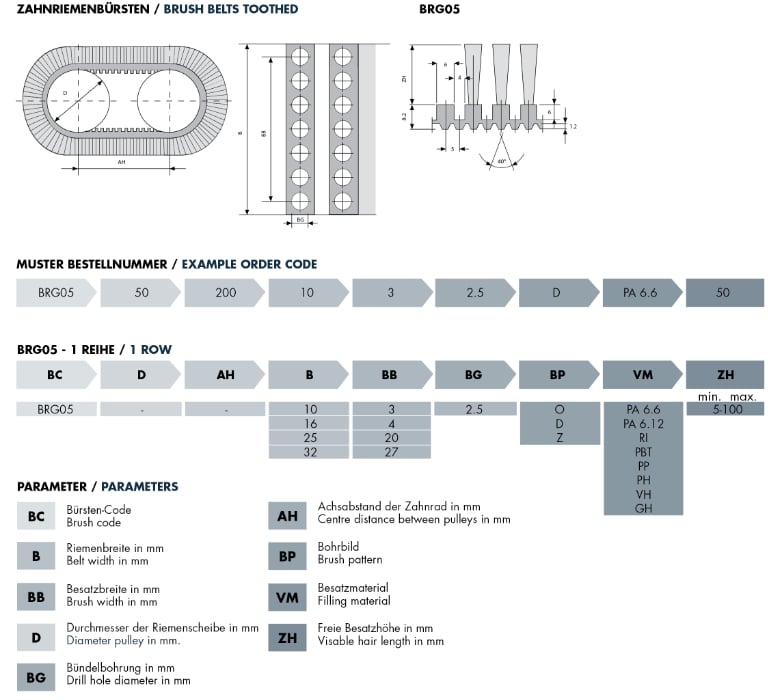

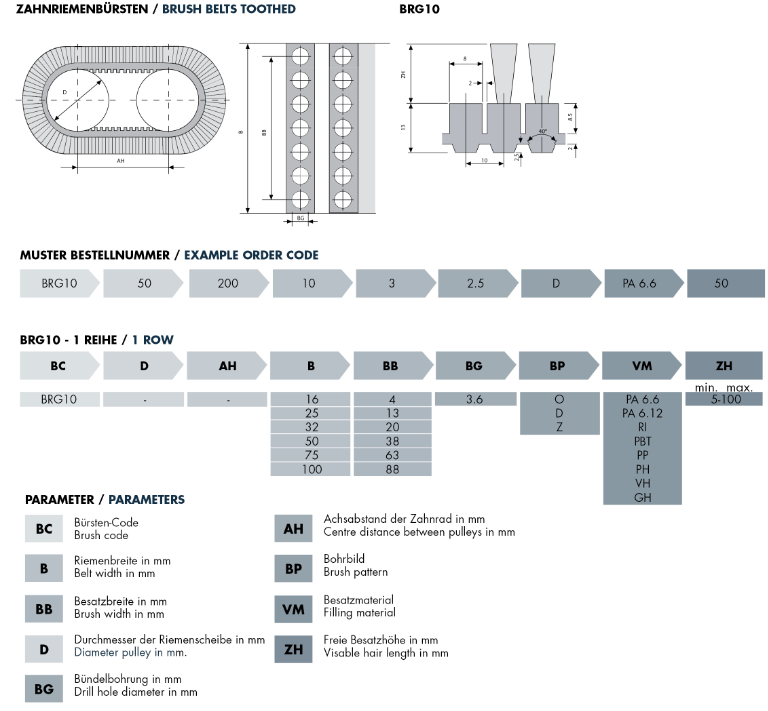

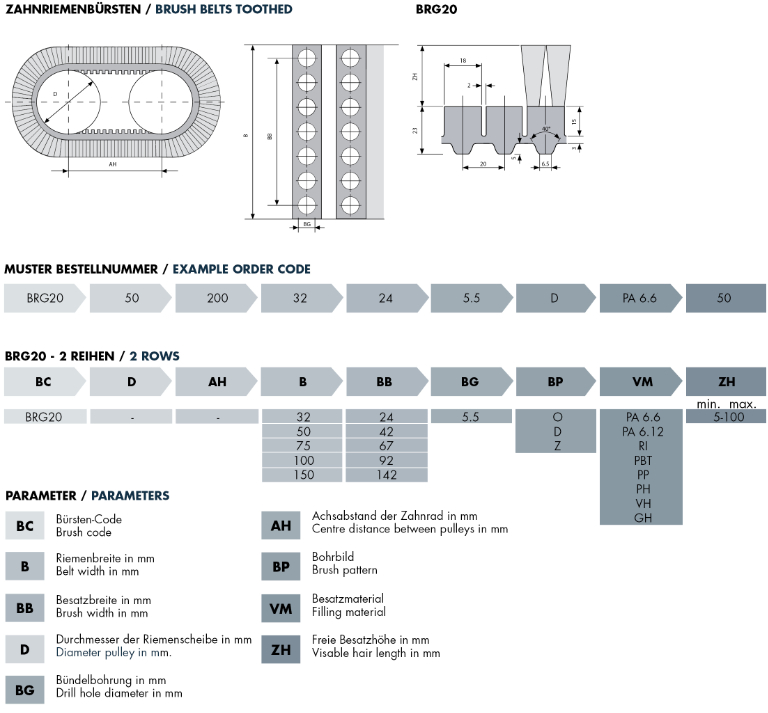

The table below shows our standard models of the brush belt toothed. Do you need a brush with different specifications? We are happy to help you with a custom-made brush. Even if you are not sure yet or want advice about a brush, you can contact the sales team.

Parameters

- B – Belt width

- BB – Brush width

- BG – Drill hole diameter

- D – Gear wheel diameter

- AH – Center distance of the gear wheel

- BP – Drill pattern*

- VM – Filling material

- ZH – Visible hair length

* Drill pattern: (O) Open, (D) dense or (Z) very dense. (Density for width). The occupancy density for toothed brush belts is limited because limited space for brush fibers is available only on the top of the belt. This means that the fill is always relatively open.

View all configuration options

| Brush belt toothed | |||

| Article number | Belt width (mm) | ||

| BRG05 | 10 - 16 - 25 - 32 | ||

| BRG10 | 16 - 25 - 32 - 50 - 75 - 100 | ||

| BRG20 | 32 - 50 - 75 - 100 - 150 | ||

Filling material

The filling material we use for your brush depends on your application, industry and product. Do you have questions about filling materials? Please feel free to contact.

| Filling materials | |||

| Abbreviation | Description | ||

| GH | Goat hair | ||

| PA 6 | Polyamide 6 | ||

| PA 6.12 | Polyamide 6.12 | ||

| PA 6.6 | Polyamide 6.6 | ||

| PBT | Polyester | ||

| PH | Horse hair | ||

| PP | Polypropylene | ||

| VH | Pig bristles | ||

Your success is our success

Find the right solution

Do you have questions about the toothed brush belt or are you looking for a different solution? Contact us and we will help you further.

Brush belt toothed

Please enter your requirements and data below. We will be happy to advise you on a brush solution that perfectly suits your needs.