Quick Snap system

The Quick Snap system consists of brush segments with which can be assembled as required to make your own custom made roller brush. Without the use of complicated tools, you can quickly and easily mount and dismount (worn) brush segments.

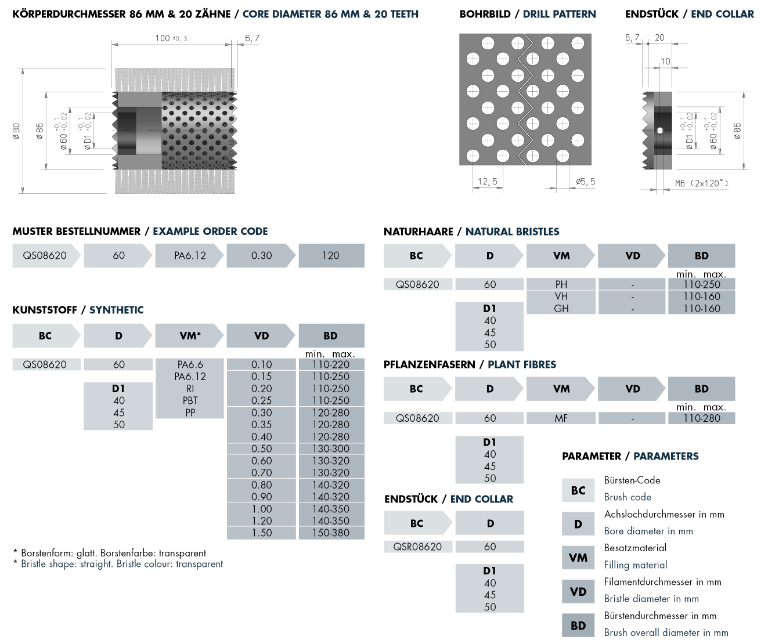

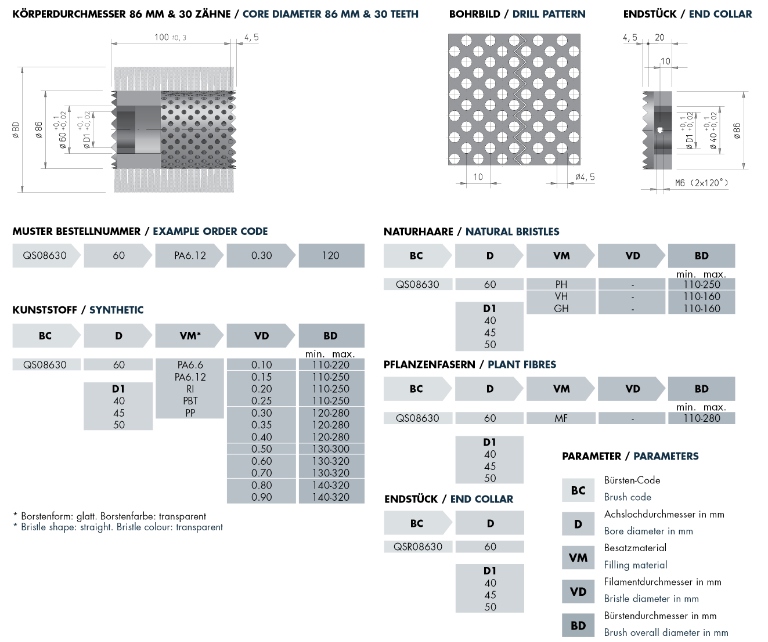

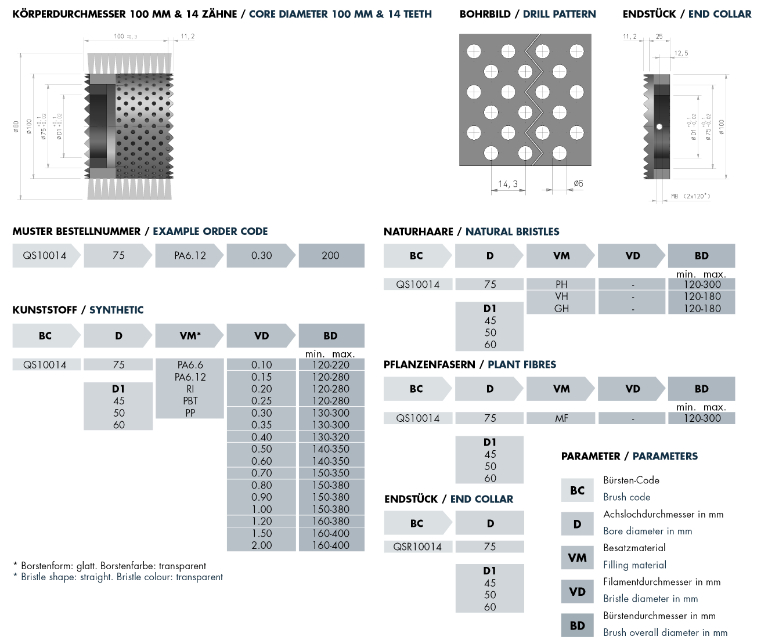

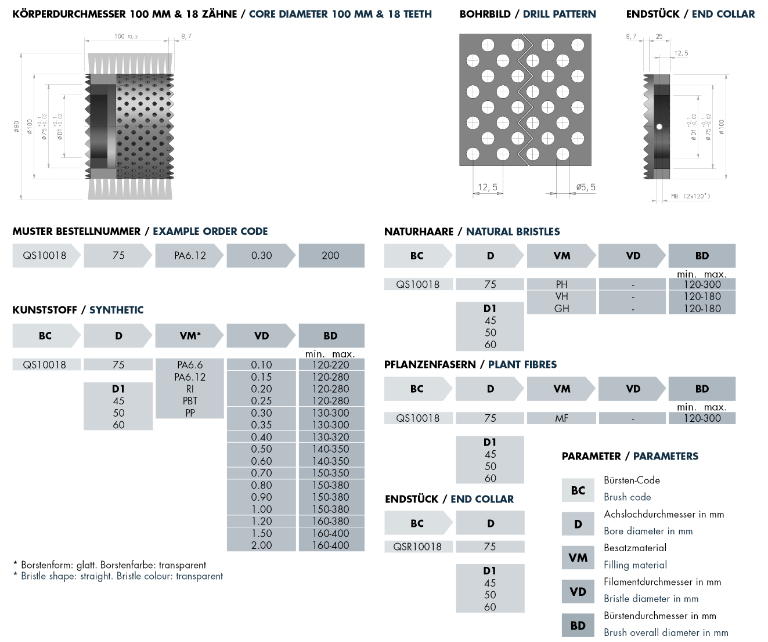

You can use this special system for many applications, such as washing, transporting, degreasing, pressing on, powdering, and sweeping. With this system, every user can replace the segments themselves. The different segments interlock via a toothing, creating an even brush surface and leaving no streaks on the brushed surface. The brushes are constructed in such a way that they can be used both clockwise and counterclockwise. For this system, it also applies that we can, in consultation with you, tailor the various elements specifically to your needs in terms of drilling pattern, diameters, filling materials, etc.

Multiple benefits

- Quick and easy replacement of worn brush elements

- Possibility to combine the system with almost any type of brush roller and core

- Saving on inventory investment, warehouse space and transportation costs thanks to loose element

Models

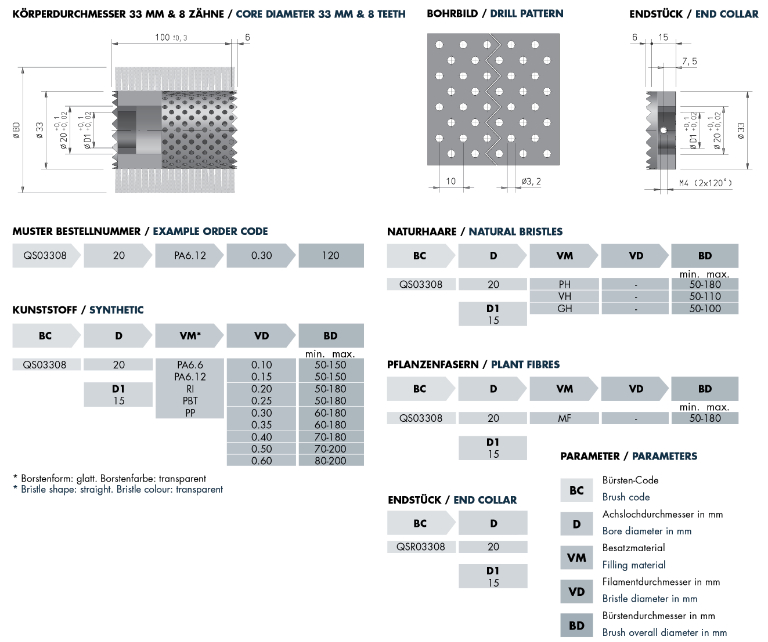

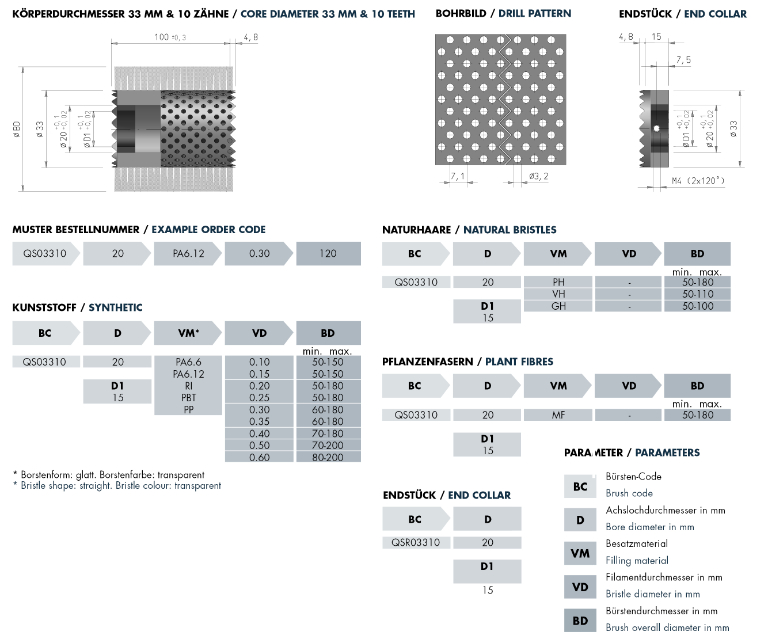

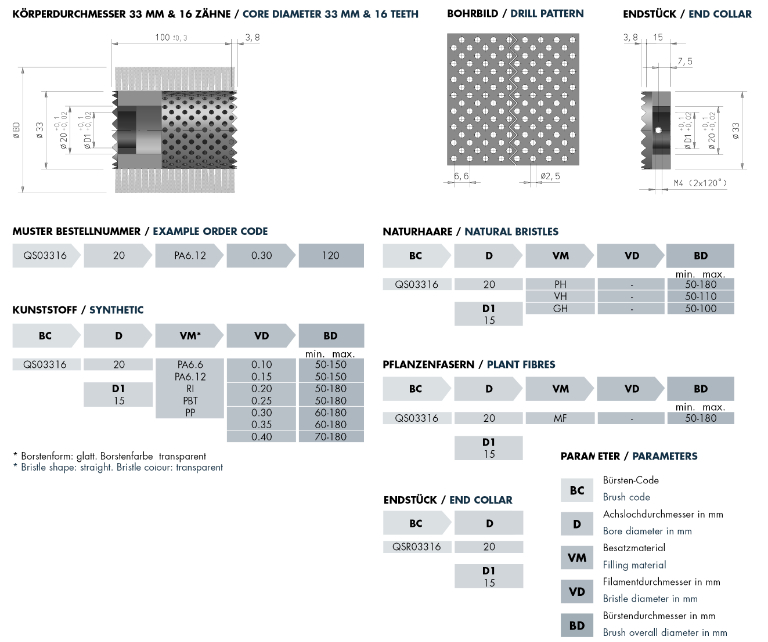

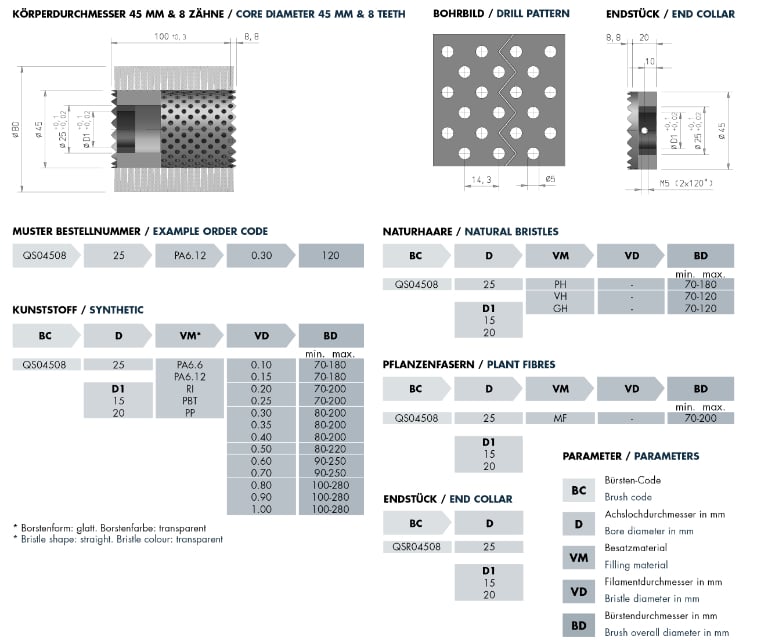

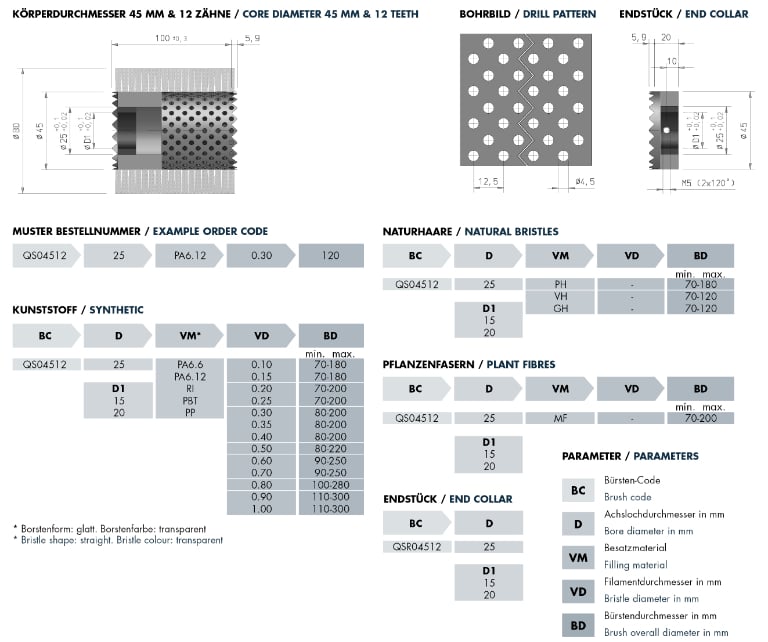

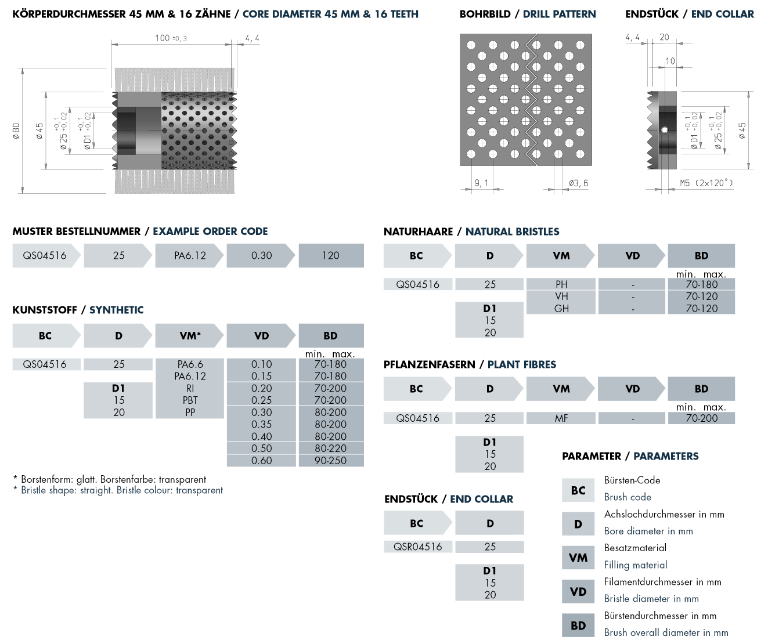

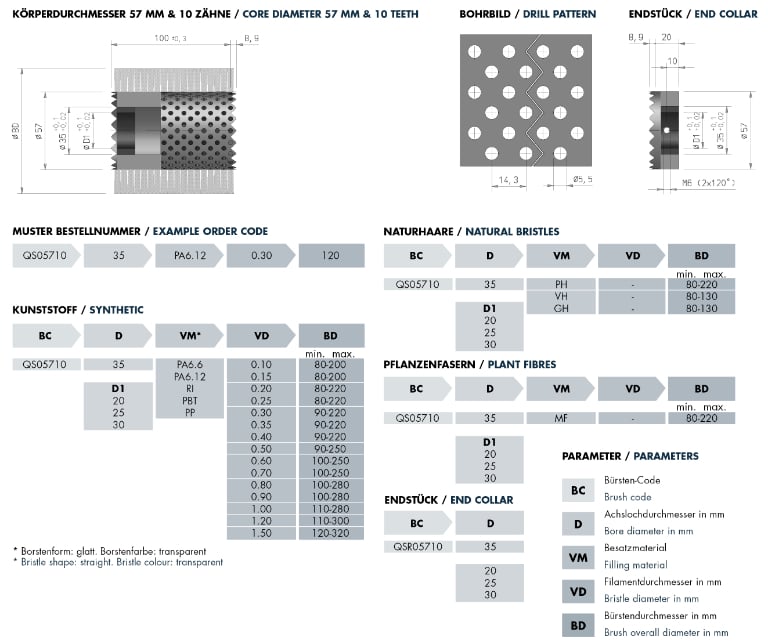

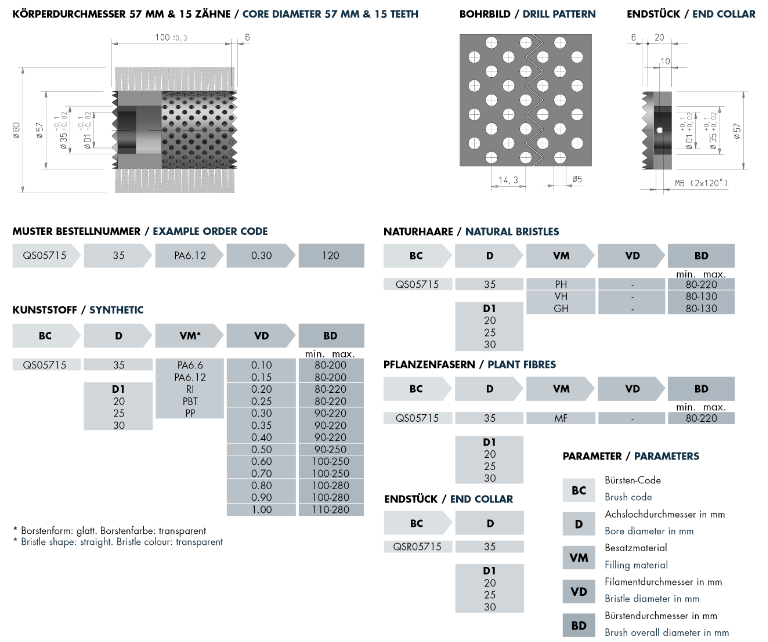

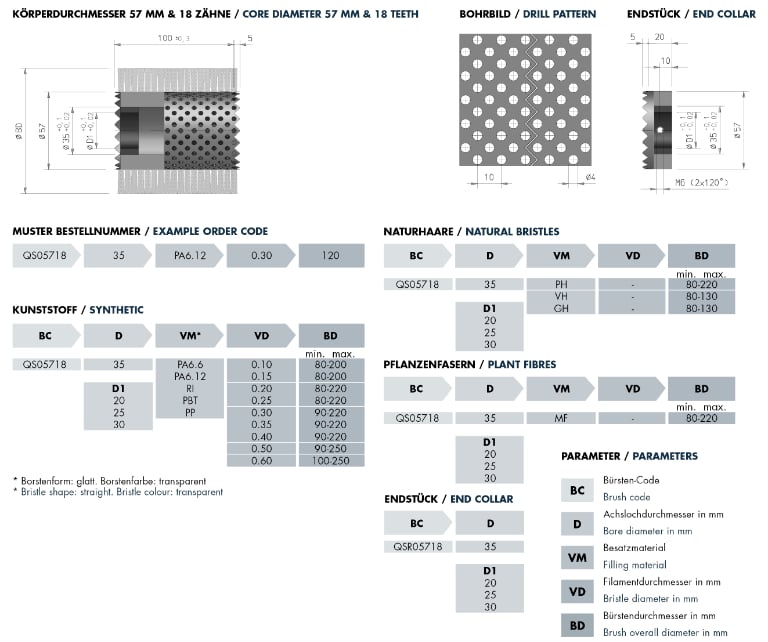

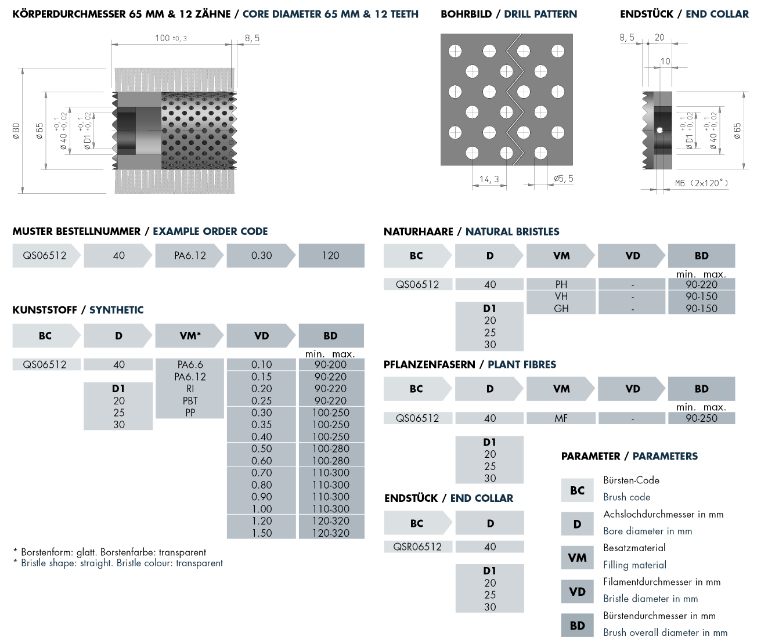

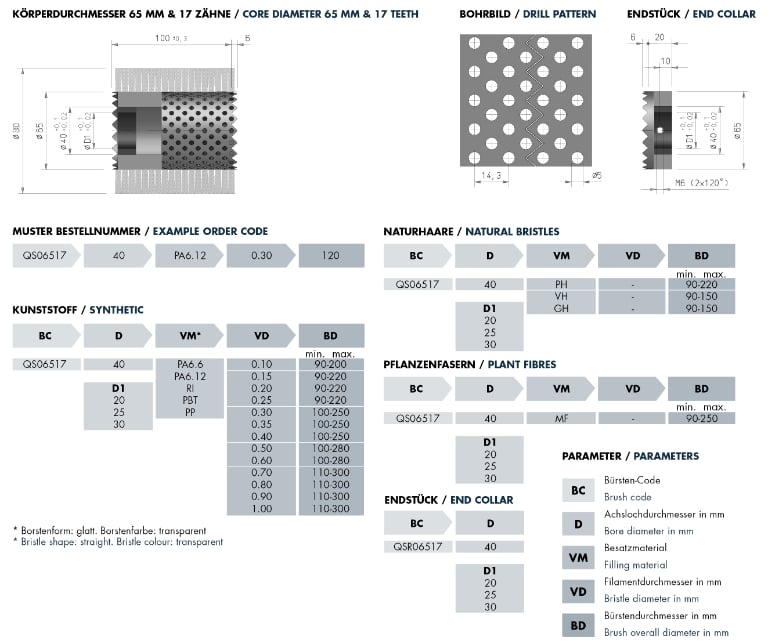

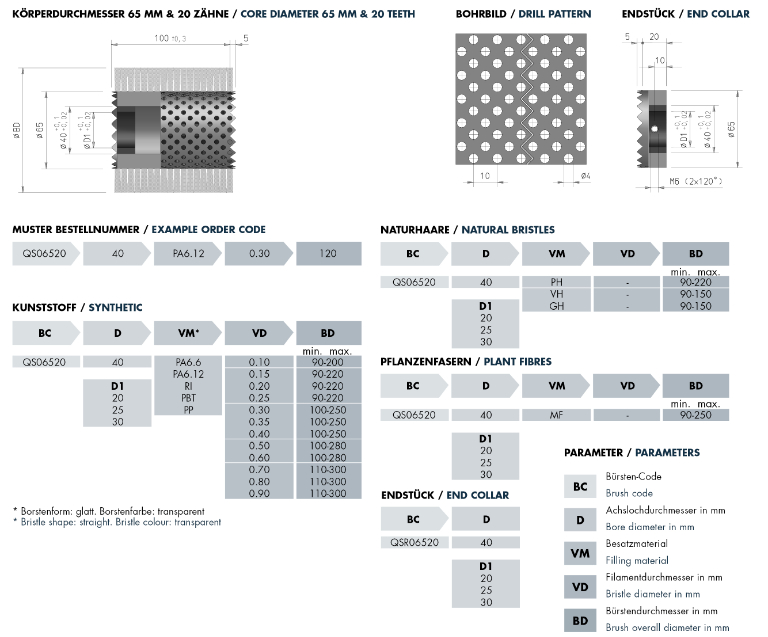

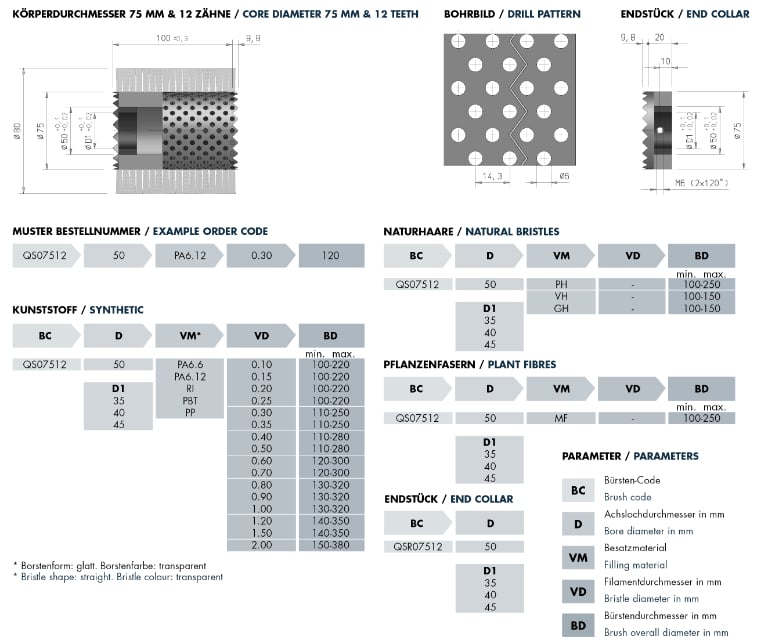

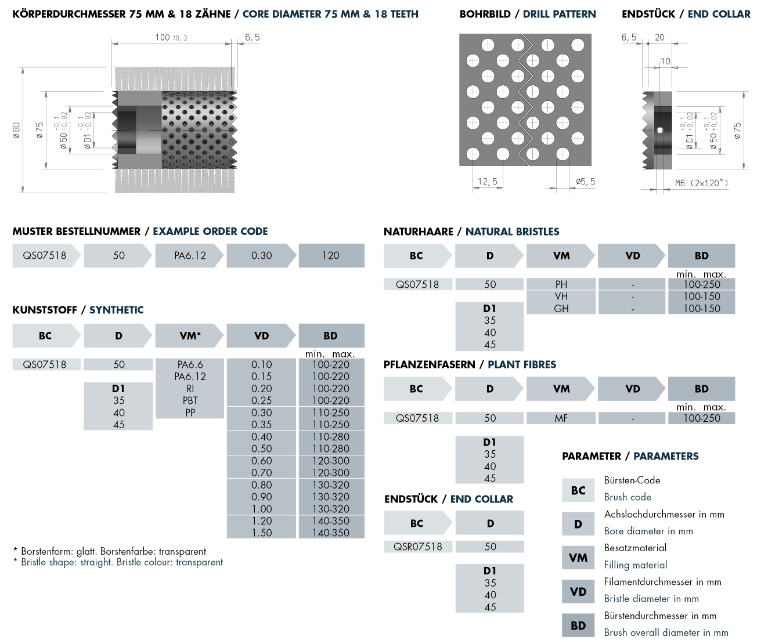

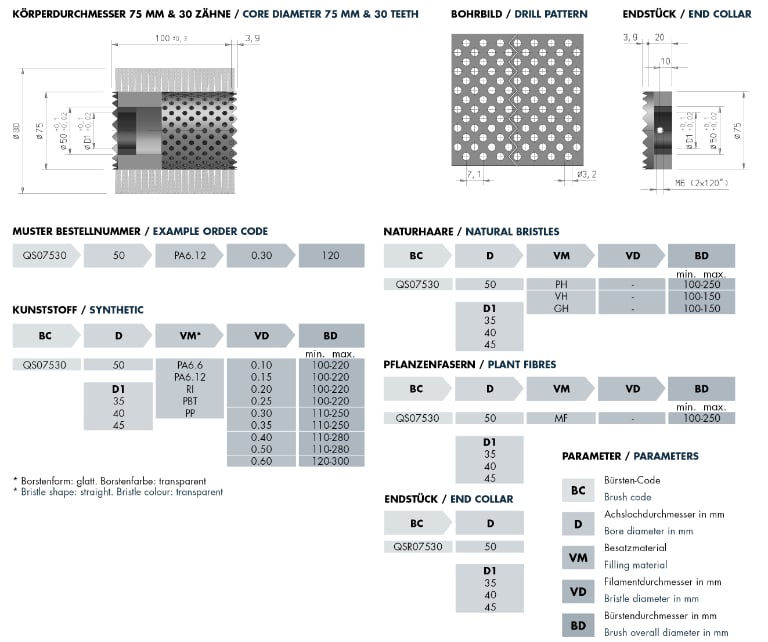

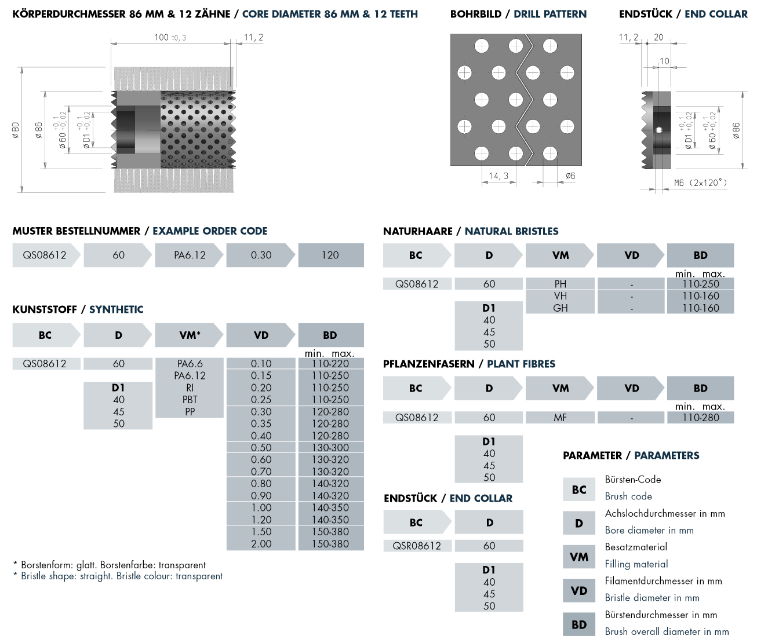

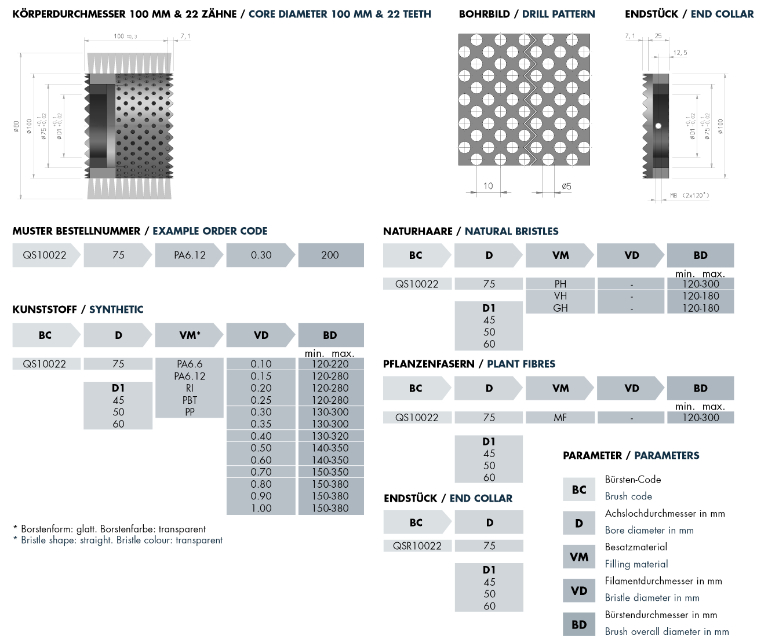

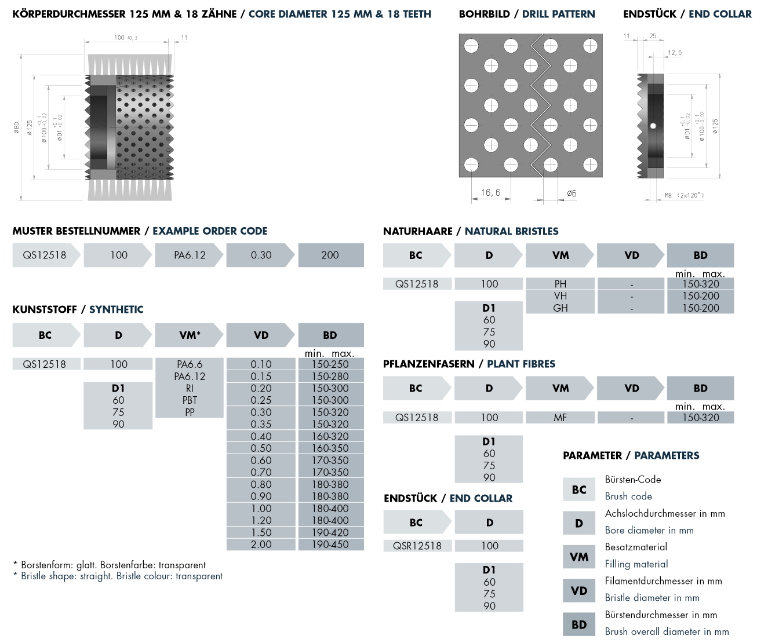

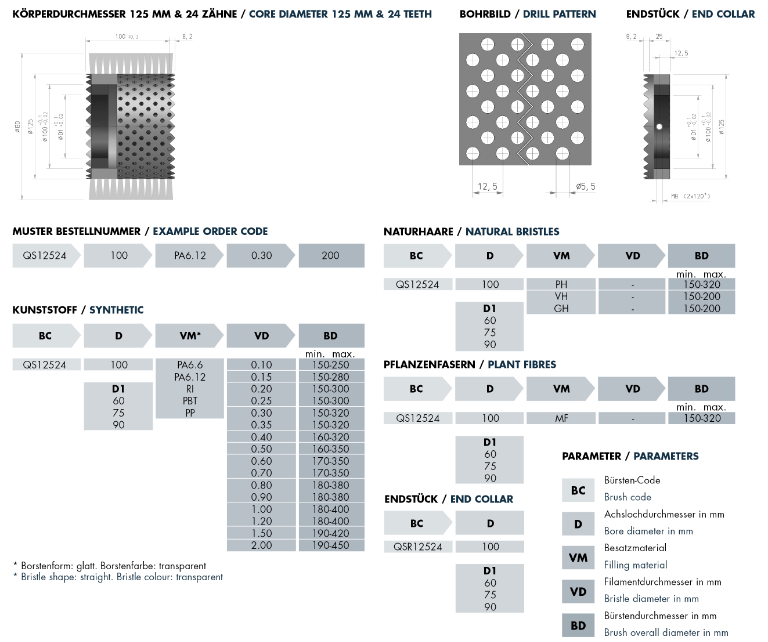

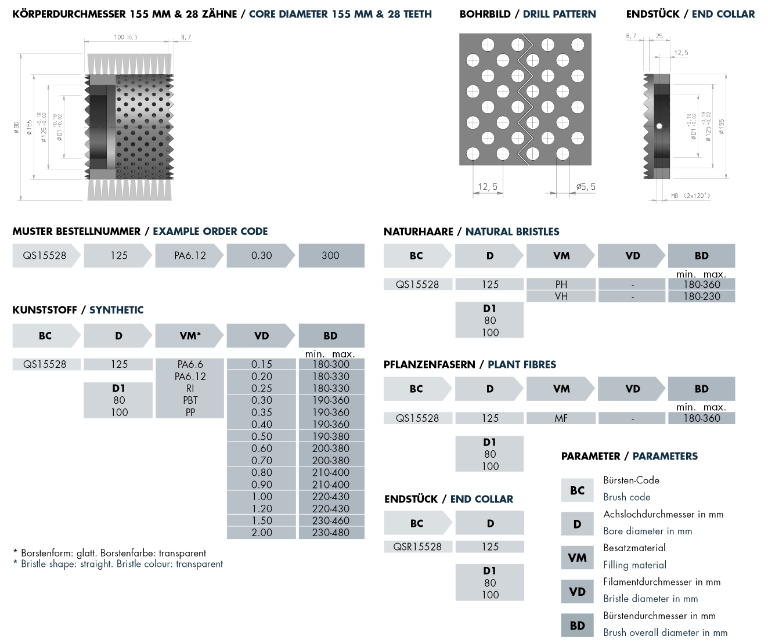

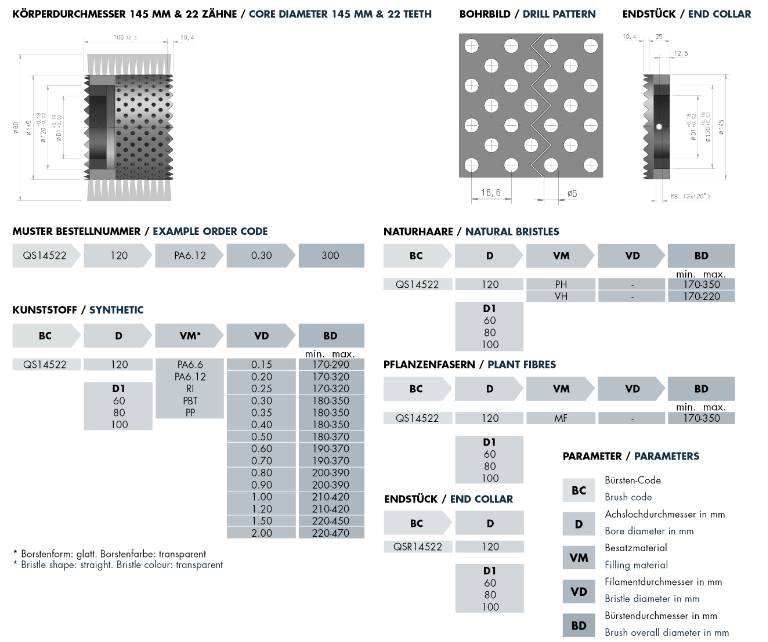

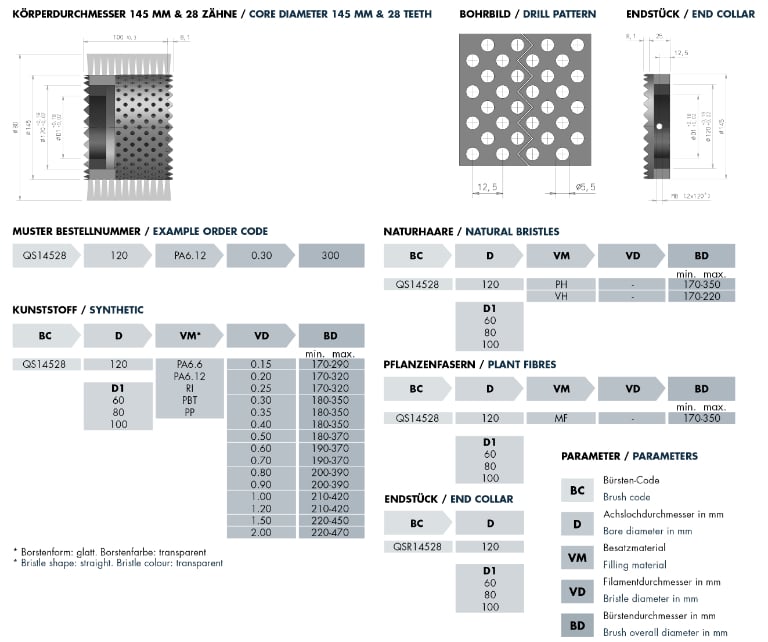

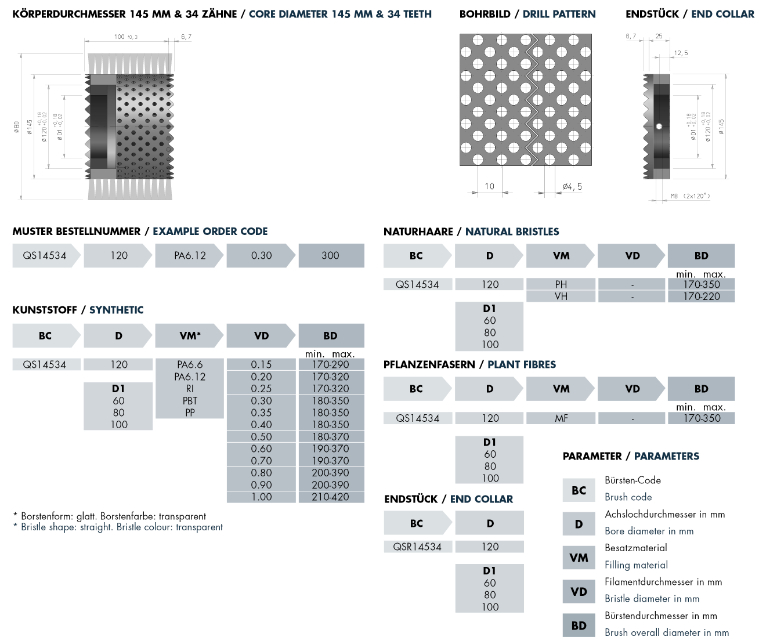

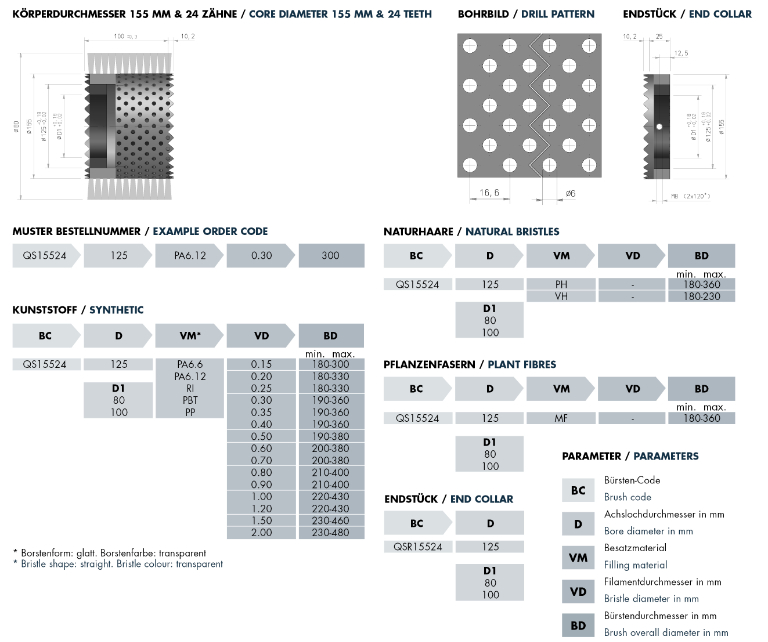

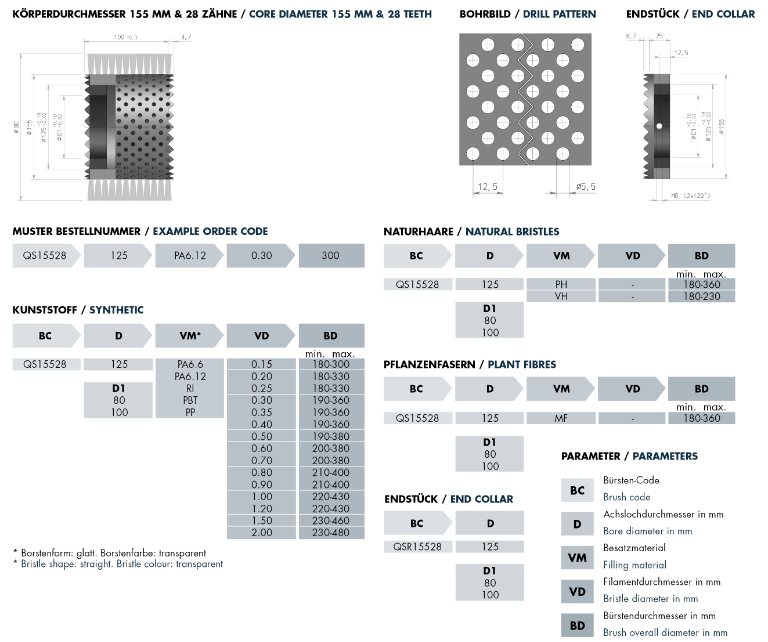

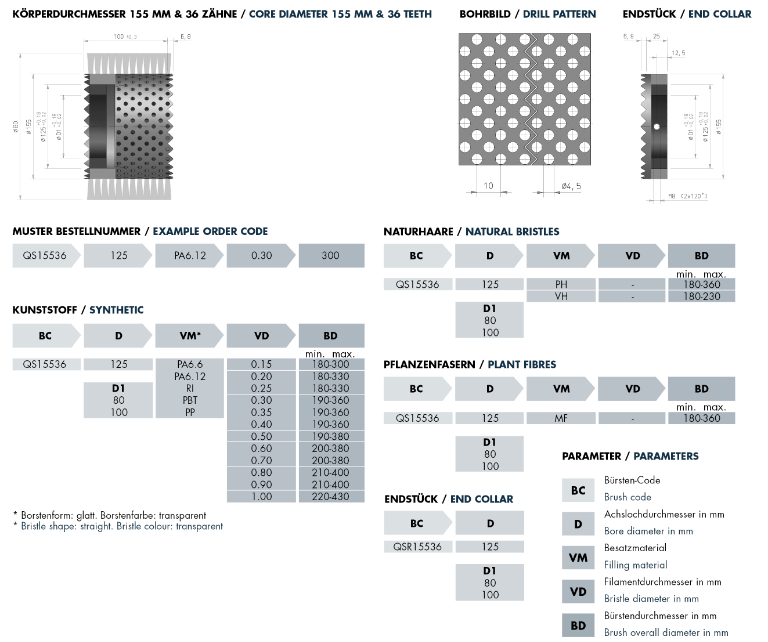

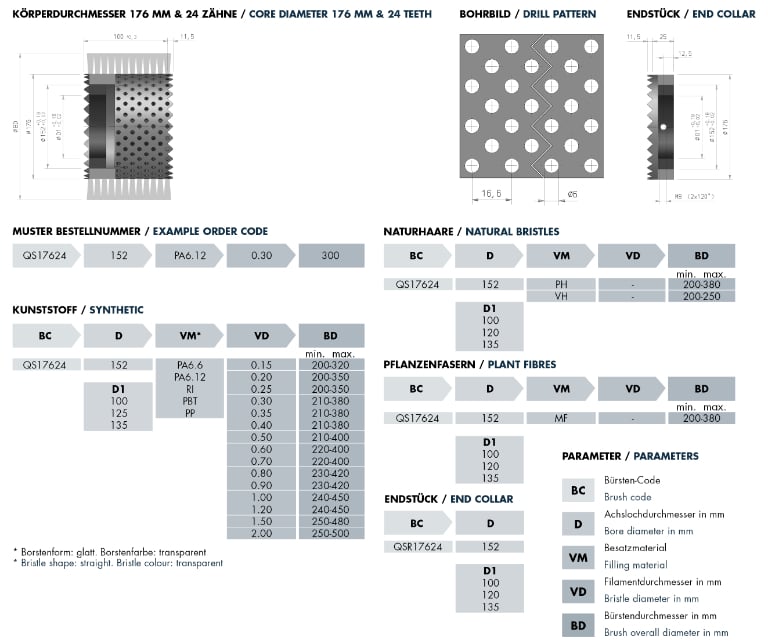

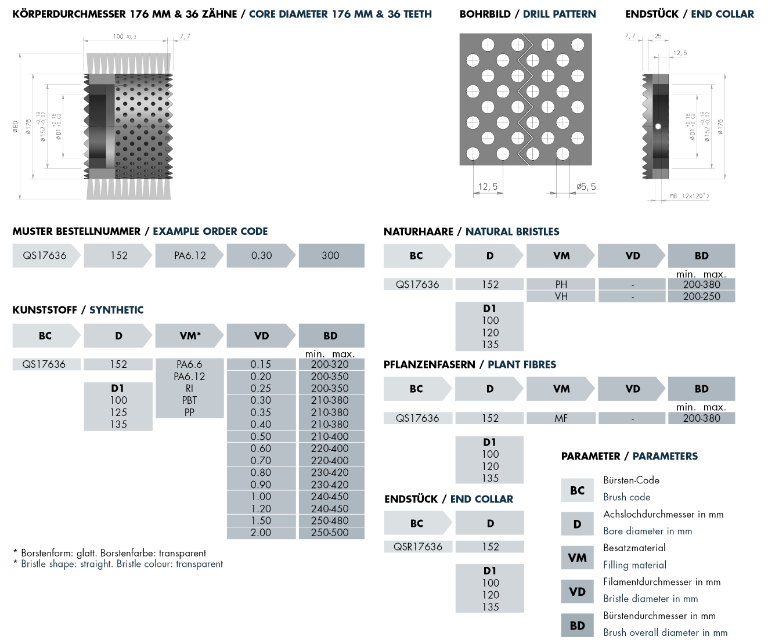

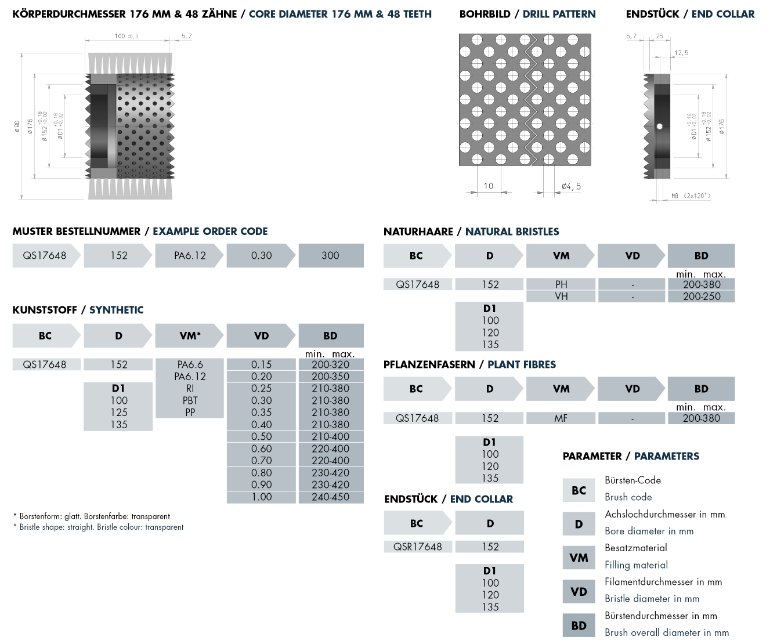

The table below shows our standard models of the Quick Snap. Do you need a brush with different specifications? We are happy to help you with a custom-made brush. Even if you are not yet sure or want advice about a brush, you can contact the sales team at any time.

Parameters

- L – Length brush

- D – Bore diameter diameter

- KD – Core diameter

- BD – Brushing diameter

| Quick Snap | |||

| Article number | Core diameter (mm) | Teeth | |

| QS03308 | 33 | 8 | |

| QS03310 | 33 | 10 | |

| QS03316 | 33 | 16 | |

| QS04508 | 45 | 8 | |

| QS04512 | 45 | 12 | |

| QS04516 | 45 | 16 | |

| QS05710 | 57 | 10 | |

| QS05715 | 57 | 15 | |

| QS05718 | 57 | 18 | |

| QS06512 | 65 | 12 | |

| QS06517 | 65 | 17 | |

| QS06520 | 65 | 20 | |

| QS07512 | 75 | 12 | |

| QS07518 | 75 | 18 | |

| QS07530 | 75 | 30 | |

| QS08612 | 86 | 12 | |

| QS08620 | 86 | 20 | |

| QS08630 | 86 | 30 | |

| QS10014 | 100 | 14 | |

| QS10018 | 100 | 18 | |

| QS10022 | 100 | 22 | |

| QS12518 | 125 | 18 | |

| QS12524 | 125 | 24 | |

| QS12528 | 125 | 28 | |

| QS14522 | 145 | 22 | |

| QS14528 | 145 | 28 | |

| QS14534 | 145 | 34 | |

| QS15524 | 155 | 24 | |

| QS15528 | 155 | 28 | |

| QS15536 | 155 | 34 | |

| QS17624 | 176 | 24 | |

| QS17636 | 176 | 36 | |

| QS17648 | 176 | 48 | |

Filling material

The filling material we use for your brush depends on your application, industry and product. Do you have questions about filling materials? Please feel free to contact.

| Filling materials | |||

| Abbreviation | Description | Advantages | |

| PA 6.6 | Polyamide 6.6 | Suitable for industrial applications, heat resistant and high abrasion resistance | |

| PA 6.12 | Polyamide 6.12 | Does not retain moisture, better resilience than nylon 6.6 | |

| PBT | Polyester | Heat resistant, abrasion resistant, does not retain moisture and certified for food use | |

| PP | Polypropylene | Does not retain moisture, acid resistant, lower abrasion resistance than nylon 6.6 and 6.12 | |

| PH | Horse hair | Flexible fiber for light brushing (e.g., for cleaning plastic strips) | |

| VH | Pig bristles | Harder than Horse hair | |

| GH | Goat hair | Extremely soft fiber for delicate work | |

Your success is our success

Find the right solution

Do you have questions about the Quick Snap or are you looking for another solution? Contact us and we will help you further.

Quick Snap

Please enter your requirements and data below. We will be happy to advise you on a brush solution that perfectly suits your needs.